Table of Contents to Clinics

- 2024 Clinics

- April 2024 – April Clinic – Backdrops: How to Paint and Blend with Mid and Foreground

- March 2024 – March Clinic – The Oregon, California and Eastern comes alive at the Colorado Model Railroad Museum

- February 2024 – February Clinic 1 – Hospital Trains

- February 2024 – February Clinic 2 – Scratch Building with Monster Modelworks Brick Sheet

- February 2024 – February Clinic 3 – Trees, trees, and more trees

- January 2024 – January Clinic – Modeling the ATSF built cars of the 50’s and 60’s

- 2023 Clinics

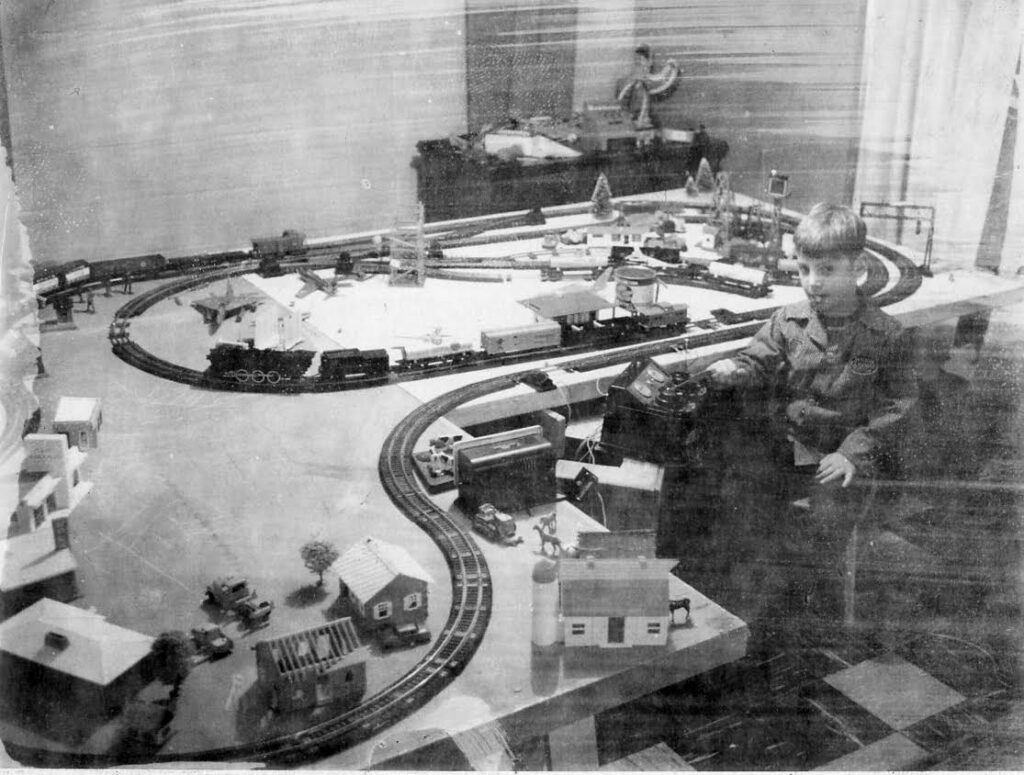

- December 2023 – December Clinic – Gathering of the Elves

- November 2023 – 1st Mini-Clinic – Sylvan Models HO Scale Laker Class Freighter Kit – Glenn Runkewich

- November 2023 – 2nd Mini-Clinic – Representation of Bath Maine – Rich Gibson

- October 2023 – Canceled

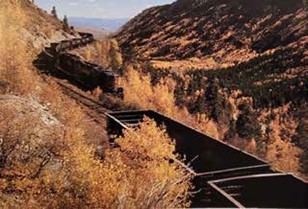

- September 2023 – The Denver and Rio Grande Western (Monarch Branch) – Gary Myers

- August 2023 – Annual Picnic

- July 2023 – Designing a Railroad for Operations Based on the Prototype – Bob Foltz

- June 2023 – Prototype Railroad Experiences and Modeling Perspectives – Kevin Ruble

- May 2023 – The Art and Science of Kit Bashing – Gerry Glancy

- April 2023 – The Evolution of a Railroad, The Education of a Railroader – Scott Ogle

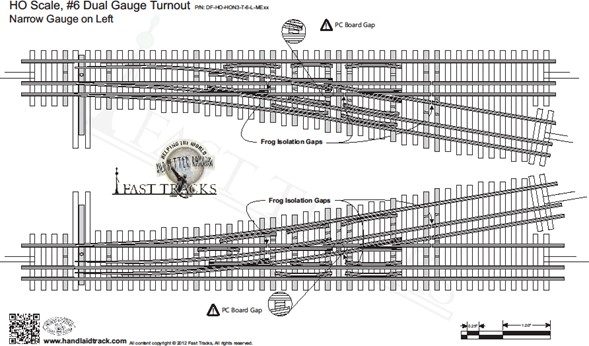

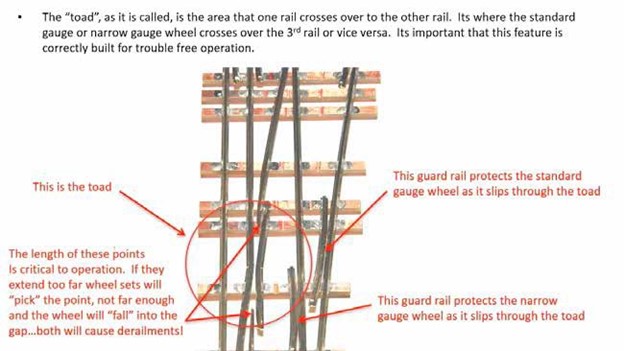

- March 2023 – Tips and Techniques for Building Dual Gauge Turnouts using Fast Tracks Assembly Jigs – Tom George

- February 2023 – Non-Flicker Lighting and Weathering Locomotives – Bill Botkin

- January 2023 – How to Become a Published Author – Jim Chiddix

- 2022 Clinics

Clinics for 2024

April Clinic – April 15, 2024

Clinic – Backdrops: How to Paint and Blend with Mid and Foreground

Mark Shifter Biography

Mark Shifter is a person with Midwestern roots and Front Range experience. Born in the St. Louis area, raised in Missouri, Iowa and Nebraska, Mark received a Bachelor’s and Master’s Degrees from the University of Nebraska-Lincoln in the mid-80’s. He spent 13 years in the Kansas City area before relocating to Colorado 23 years ago. Mark has been a licensed architect since 1991 and has his own practice designing residential and commercial projects. While architecture is a passion and his livelihood; he is also a musician and songwriter and dabbles as an artist as well.

Mark Shifter has been painting backdrops in this fashion for about 17 years. Mark will use a PowerPoint presentation to step through his process. He utilizes three levels of finish that he will discuss, with photo examples of each level. He will illustrate the paint and brushes he uses, and then he will give a live demo on how he creates his backdrops.

Mark Shifter, modeler of the Franklin Southern Murphy Subdivision, presented a clinic on “How to Paint Backdrops and Blend with the Mid and Foreground”. Mark started the clinic with an overview of his journey as an artist. He is a practicing Architect, where his work is connecting the constructed world to the people using it. He also painted some mixed media artwork that is on display within his home and the entry of the layout area. His most ambitious effort to date is the painting of the backdrop scenes on the Franklin Southern Railway. This is a large discontinuous art project, over 120 feet in length, using mixed photo backdrops and painted scenes to blend the countryside to match and complement the true actors on the stage, the model trains.

Photo backdrops are useful for modeling. They offer highly realistic scenes using commercial backdrops or created from your photographs. Utilizing editing software, the scenes can be blended end to end for a continuous photo scene.

The drawbacks to the photo backdrops are the cost for large layouts, the learning curve for editing software can be steep, and the installation is challenging due to the length of the photos and matching lines for concurrent scenes.

On the other hand, painted backdrops are completely flexible with custom scenes and a high level of specific detail. The cost of the materials for the painted backdrop is relatively low, but the true cost is in the time required to envision and execute the painting. As with most modeling efforts, the results may not meet your expectations without a great amount of practice.

Utilizing painted backdrops in combination with the photo elements, the perspective can be adjusted to suit the viewers. This allows one to be transported to western North Carolina within the Smoky Mountains. Mark was able to create accurate depictions of his chosen layout design elements around the layout. Mark was inspired by several artists and modelers in his efforts. These include James Michael Smith, a YouTuber; Mike Danneman, a published artist and N scale modeler; and Tom Johnson, a model railroader and artist. They all create scenes to transport the viewer to the locale within the chosen perspective.

The materials that are used for the painted art are:

- Craft acrylics

- Tube acrylics

- Latex paint for blocking

- Oil paints

- An assortment of brushes, generally a less expensive variety

- Colored pencils, used for highlights of tree branches, pavement, curbs, sidewalks.

The chosen or mixed colors are to match or mimic the scenery materials used. The ground cover, trees, and shrubs are mated to the paint colors. Paving colors are carefully matched to the adjacent scenery material color for a seamless match at the intersection.

The scenes are blocked generating the basic shapes and flow of the landforms. This gives the start of the backdrop and allows for visualization of the land shapes and reference between the foreground and background relationships. These are latex or acrylic paints that will be covered by future painting.

At this point in the process the paint colors are mixed to match scenery foliage. The tree canopies are painted forming tree shapes in the canopy. To add depth and realism to the scene the colors are varied to provide contrast and definition from the light to dark areas.

The final details are added to the scene with lighter contrasting color blends to better define the canopies and add in more defined foliage.

A surprising element of blending the photographic and painted elements is the brightness of the photo colors. To assist in matching up the color palette, it is suggested you experiment off the layout with the colors and photos to obtain a critical color match. In blending the elements of the backdrop, it is a good practice to use trees and shrubs to hide the seams and transitions.

Mark shared a number of scenes from his layout to illustrate the successful use of these techniques.

Scenes from the papermill area on the layout. Note the background mountains in blue tones with the foreground hills in the green tree canopy colors.

From above, the left photo shows a painted background scene with the parking area as a photo insert. The chain link fencing was added to the scene using Prismacolor color pencils. These are useful for blending colors and there are a variety of colors from which to choose.

The right photo shows Photoshopping the road on the backdrop can be modified to a differing alignment adding depth to the scene.

The left photo shows the use of a photo only backdrop. This is a photo of Franklin which is situated outside of the Smoky Mountains and offers more open terrain. The right photo illustrates Mark’s technique to add build flats to the scene. The photos of buildings were sized in photoshop to give a 7-foot-high model door height. The buildings were blended together in a reasonable order to provide the building backdrop in front of the painted trees and hills behind. The building photos were mounted on a cardboard backing.

As a finale to the presentation, Mark demonstrated his painting techniques. The acrylic paints used can be blended to make matching colors to the photos or to the existing painted scenes on the layout. He modifies the photos to remove unwanted elements like phone, power or fence lines.

This is the basic blocking on the painting/ backdrop. The shapes are roughed in using base colors. The base of the painting has the beginnings of a roadway. This is 24 scale feet wide. The roadway will curve off into the distance as the painting progresses. Using the dark acrylic paints the tree canopy is added to the scene with a stippling motion. Build up the colors, going to lighter shades in this case, use cadmium yellow.

The color guide is the scenery materials. This is a guide to reproduce the colors from scene to scene and session to session. He uses inexpensive brushes so that you can replace them as necessary. There was a good deal of discussion on the brushes and paints. The key to the technique is the laying of the colors to differentiate the tree foliage and the grass ground cover. The road was added to the painting at the lower edge curving into the background. Road striping was added to the road with colored pencils. The road shoulders were modeled with colored pencils to replicate the gravel. Pencils were also used to add in branches to some of the foreground trees. This is a tremendous set of skills to add to your modeling.

As with all techniques, practice is the key. Remember if you don’t like the result just paint over it and try, try again.

March Clinic – March 18, 2024

Clinic – The Oregon, California and Eastern Comes Alive at the Colorado Model Railroad Museum

Bill Kepner Biography

Bill grew up on the east coast, migrated west for college and a career, and ended up in Fort Collins where he worked as a Software Engineer for many years. Has a great wife, Cindy, and two adult children, one of which is a locomotive mechanic for a regional railroad in South Dakota. Non-railroad hobbies include photography and Arduinos. He has been the Director of Operations at the Colorado Model Railroad Museum since November 2023, where he tries to keep things fun for CMRM guests and volunteers.

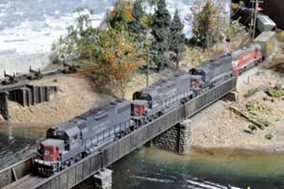

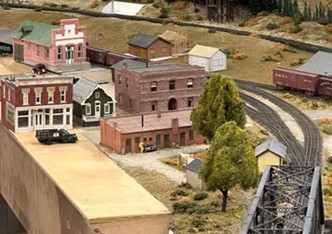

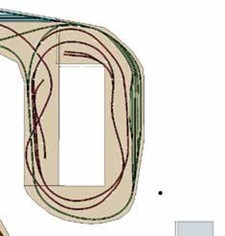

This is an HO scale model railroad housed in the Colorado Model Railroad Museum in Greeley, Colorado. The railroad occupies around 5,500 square feet of the 10,000 square foot museum space. The museum and railroad are an outgrowth of David G. Trussell’s love of trains and model railroading. Mr. Trussell spent a great deal of time in Oregon and was enchanted by the logging railroads of the area. He was active in modular railroading in Oregon and after moving to Colorado continued those efforts. The modular group he was a part of developed a 64 foot by 64 foot modular layout that was set up at numerous train shows.

Mr. Trussell was always doodling railroad plans and based this interest, on a May 1951 article in Model Railroader by Linn Westcott, “If I had a Million Dollars”. The article named a number of elements for this fabulous model railroad; high ceilings, few windows, easy entry way, lobes or peninsulas, yards at each end, spotlights highlighting the elements, a balcony for viewing, CTC machine for routing control, and mountains at eye level. Since this was 1951, the article did not anticipate DCC control or mechanical improvements to the trackwork and rolling stock.

He retired and wanted to give back to the community. His original idea was to construct a model railroad as a park or museum in the community with the city assuming responsibility. The City of Greeley was not convinced it should be a participant and declined the idea. At that point, the Colorado Model Railroad Museum became a 501 (c )3 nonprofit with an independent board of directors. The museum opened for public visitation in 2009.

The model railroad was constructed using well defined standards and practices to maintain the integrity of the railroad and withstand the rigors of public use. The trackwork was executed to be faultless, with the only track caused derailments to be a faulty turnout.

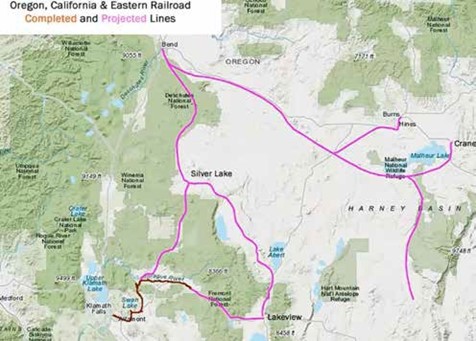

History of the OC&E

- 1909 – Southern Pacific arrives in Klamath Falls.

- 1917 – Ground broken for Klamath Falls Municipal Railway.

- 1922 – Track completed to Sprague River.

- 1927 – Southern Pacific buys the line.

- 1933 – SP and Great Northern begin joint operations.

- 1975 – Weyerhaeuser buys the railroad.

- 1991 – Abandonment approved.

- Right-of-Way acquired by Oregon State Parks.

Lakeview Oregon was the terminus of the Oregon, California and Eastern Railroad. The depot was purchased by Mr. Trussell. The line was abandoned by Weyerhaeuser in 1991. The line exists in part as a biking and hiking trail by the Oregon State Parks, as the OC and E Woods Line State Trail. The model railroad captures the look and feel of the rugged terrain and the surrounding area with the backdrops and the on line topography. The route tied to an extensive and changing logging railroad network in the mountains north of the railroad and west of Summer Lake in southern Oregon.

The route was operated by Southern Pacific and the Great Northern on a 5 year alternating basis. The maintenance on the line was deferred in the hopes the next operator would shoulder the capital expense. This ultimately led to Weyerhaeuser purchasing the line and operating the final stages of its existence. The line tries to run prototypical engines and equipment. There is a logging turn that runs from Klamath Falls to the logging loadout on the hill and returns. There is an opportunity to run logging equipment with geared locomotives and long strings of skeleton cars of logs.

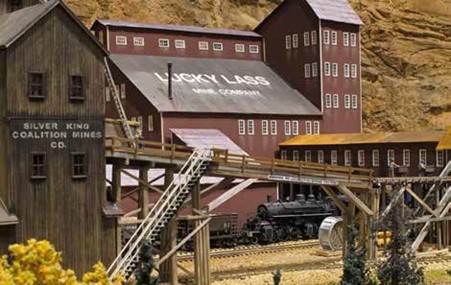

Mining interests are represented on the railroad with Lucky Lass Mine Company, which is a stretch on the prototypical line. The line is populated with HO figures in action along the line. There is a switch job to switch the logs into the mill pond. To add to the action, a local passenger train is run along the line for the hunters, hikers, and fishermen to points along the grade. The line extends to a port where ships are loaded with lumber. The ship models were intended to be floated in water, but with the passage of time, it was determined that they should be fixed.

In an effort to make the line handle more mainline traffic, the Indian Reservation on the mainlines in the area were set to charge a car fee within their lands. This meant that the OC&E would provide a cutoff for this traffic and bypass the fee.

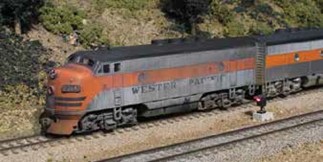

The layout is set in the 1975 era, but steam power stills has a showing on the rails. As a perk to volunteers, they may bring their own equipment to run on the layout. This leads to a mix of railroad heralds and varied time frames, including during a certain period, the Pioneer Zephyr from the Burlington railroad makes an appearance for passenger traffic.

As there are many photographs taken of the model railroad, sometimes volunteers and staff members find themselves within the images.

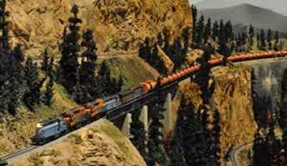

U18B locomotives are found on the railroad as the Museum made a deal with Intermountain Railway for a special run. The OC&E has online traffic and logoed locomotives, and equipment are in evidence. Within a logging area railroad, one would find a number of large timber trestles to carry the rails over ravines and rivers. The OC&E has a number of impressive models. The model railroad is associated with SoundTraxx, and the models are mostly equipped with their sound decoders. The model railroad is all CTC signaled since the beginning. As a part of Bill’s responsibilities, he is assuming the electronics for the railroad, which means a great deal of learning and a little detective work on the components.

One of the operating challenges is “The Glow Worm”, an eighty cars short tank car train. This train will not fit in any siding, nor is it to be run by less experienced operators.

The layout is to be open for the Rocky Ops weekend. The crews are currently working on fine tuning the railroad and jobs for the visiting operators.

The Ski Train makes an appearance as Rapido Trains produced a Ski Train in the past and requested the Museum make up a video of the equipment in the mountain scenery of the layout. Locomotives wear out quickly on the layout as it is a long layout and runs six days a week in the summer.

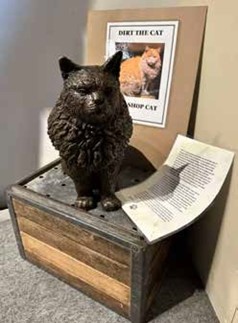

Other items in the museum include some railroad memorabilia. “Dirt the Cat” has a bronze statue displayed at the museum. This is the shop cat found for many years at the Nevada Northern Railway in Ely Nevada. When the cat passed, three bronze statues were cast, and the museum was the recipient of one. There is a full-size Colorado and Southern caboose displayed. The Lionel train wall display is found at the museum. In addition, a Department 56 collection was donated to the museum and is in part displayed. Hopes for the future include expansion where the entire collection may be displayed. The Caboose Hobbies equipment display is located at the museum, including the aprons, photo of the building, and the historical collection that was in the store. A modest size Lego layout is found at the museum supplied and maintained by the local Lego users’ group. A newer addition to the entry are statues welcoming one to the museum and railroading.

Special events are hosted by the museum regularly to entice the public to visit and share the experience. A small N scale layout is on-site with a larger layout in storage. The expansion would include space for this layout and in the future a garden railway to expand the museum offerings and interest for the public. A youth program to build T-Trak is on display. The museum is hosting an RPM meet this September for one day. This is an organized show and tell with rail modelers showing their efforts and discussing the tools and techniques used to build and detail the models. It is open to all modelers and all scales.

The museum has a building that was donated for their use. It was a warehouse building and is not suitable for public use. There is planning in progress to see how this could fit the museum and if it can be repurposed or needs to be razed for a new structure.

The final item on the agenda for the presentation was a video of the local cab train ride through the layout. This is a ¾ scale representation of a diesel cab with the throttle and brake tied to the locomotive on the model rails. This runs the visitor through the layout and shows the total layout trackage in the view screen. This gives the visitor a look at hidden scenes on the layout and a really interesting ride. This may be offered to the public later. Currently the volunteers see this as a track inspection device. The only real drawback is that the tunnels are not scenically modeled inside.

The modelers will add whistle signs to the grade and station signs either on the signal box or on separate signs. Questions included the track code used which was code 83. Mainline switches are all hand laid. The layout was DCC controlled from the beginning. When insufficient operators are available, the layout can run on Auto Ops. This is an electronically controlled operation that controls the trains for operation in the absence of an operator. The rockwork is hand carved or cast throughout the layout.

February Clinic 1 – February 19, 2024

Hospital Trains

Gerry Glancy Biography

Born, raised and educated in California, fortunately in an era when public schools were high quality and enjoyed wide public support. Graduated from medical school in 1966 at which time (Viet Nam) a special set of laws covered physicians. The vast majority of new grads faced a two-year military commitment in some form or other. So, he signed up for two years to “get it over with”. Fourteen years of active duty later he was still “getting it over with”. It was actually the US Army that sponsored his training in pediatric orthopedics surgery. Finally deciding geography was more important than furthering his military career, he settled in Denver and joined the staff at The Children’s Hospital. Ironically, he retired from the same location he had trained in orthopedics, Fitzsimons. Now watching 7 grandkids grow up with the satisfaction of knowing he’s able to facilitate some of their adventures, including model railroading.

Heavy loads of wounded landing at U.S. ports to distribute patients for their rehabilitation to multiple military hospitals throughout the country. This includes Fitzsimmons located in Aurora.

This presentation covered the design and construction of hospital trains primarily during WW 2. The use of hospital trains began in 1854 with Battle of Balaclava, during the Crimean War. The use was expanded during the Civil War by using passenger cars to transport the wounded. In WW 1, the cars were refitted to carry wounded on litters, and nurses to care for the wounded. The friendliness of the nurses was questioned by the presenter, but it is doubted that he had any firsthand experiences during this period.

World War II ushered in a revised scheme of care for the wounded. They were first sent to a battalion aid station to receive initial care. The next stop was the field hospital for additional treatment. The wounds were not closed for a period of 5 days to allow infection to declare itself. This method of treating battle wounds extended to the Vietnam War era. Back to WW II, the hospital trains started in Europe to transport the wounded to the ports to return home. The trains were not fancy, just rehabilitated boxcars or other rolling stock traveling on hastily repaired railroads. Travel was dangerous as the rail lines could be damaged by raids. Weaknesses in the system could be found by the loaded trains. At the European ports, the wounded were loaded onto hospital ships. These were not Navy ships but rather converted Army troop ships, twenty-four Army ships in total.

After sailing homeward, the ships landed at one of five ports, New York, Hampton Roads, Charleston, New Orleans, and San Francisco. The hospital train took the patients from the ports to hospitals located around the country, generally to get the patient closest to home, but also the facility was selected to offer the appropriate care for the nature of the injury. Burn victims were sent to San Antonio for treatment. For hand injuries Valley Forge was the leading center for treatment. Along with the wounded, the combatants were also fighting disease. Malaria was one of the common aliments but during WW II tuberculosis was also a major aliment. Fitzsimmons Hospital was specifically built for the treatment of tuberculosis.

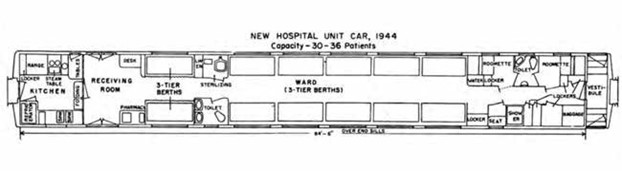

At the outset of WW II, no hospital trains were available in the U.S.. The initial solutions were not really solutions. The Pullman cars could not be easily modified to handle litter patients. The dining cars that were a part of the passenger system were not flexible in diet, cleanliness, or scheduling to handle the hospital passengers. The solutions were to utilize army troop train kitchens for the meal preparation operated continuously for the hospital cars. Three special ward cars were designed. One was a ward with only 32 patient capacity on two tier berths. This had wide doors for loading and unloading. The star of the army cars was the Unit Car. This was a train within a train. It was equipped with 3 tier berths for 30 to 36 patients. The car contained a kitchen for food

preparation and a pharmacy. It also had two roomettes and toilet/shower facilities. This car could operate singly or as a portion of a hospital consist. All of the Army hospital cars were air conditioned.

The special berths in the unit car were for psychiatric patients. This is an aspect of combat that carried different terms for the escalating conflicts. In WW 1, it was termed Shell Shock, and in WW II, termed Combat Fatigue. The term today is Post Traumatic Stress Disorder, PTSD. The British had similar hospital trains, but with differing language. The trains were organized with a set number of ambulatory seats, bunks for litters, and 1 to 2 padded berths for the combat fatigue patients.

Finally, there was the question of staffing for the train. Initially, the cars were crewed by staff shanghaied from the port hospital. This left the hospital short staffed, so a permanent detachment was formed for the hospital trains. This staff was one to two doctors, one nurse, and 5 to 6 army medics to care for the patients.

To make the system work, the debarkation hospitals basically dispatched the trains. This was an anticipation of the needs and a determination of the destinations. The trains would be from a single unit car to an 18 car train. The trains would be made up of unit cars and ward cars in a fashion to allow the division of the train at junction points to allow the patients to be directed to their treatment hospital. The routing was determined to minimize the dead head moves allowing the back haul of the train to redistribute patients to additional treatment facilities or local hospitals. It helps to remember that the strength of the U.S. military is logistics, and this was simply a logistic solution. The railroads that participated in the exercise basked in the glory of the Army system.

The hospital trains drew from a list of equipment including 120 Pullman conversion cars, 128 ward cars, 202 unit cars, and 60 kitchen cars. This equipment was used on 40 hospital trains on any given day. The results were from May 1945, when 47,044 patients were moved, and the total for the conflict was about 500,000 patients. The numbers were not easily determined for the total movements as the beginnings of the service were on makeshift cars. General Eisenhower took time to recognize the hospital train moving through his hometown of Abilene, Kansas after VE day.

February Clinic 2 – February 19, 2024

Scratch Building with Monster Modelworks Brick Sheet

Glenn Gibson Biography

Glenn Gibson was born in Dallas, Texas, but grew up in the small town of Plattsburg, Missouri, just outside of Kansas City. Glenn’s dad was the International Harvester dealer there, which provided Glenn with summer employment during his teenage years – mostly working the parts counter, but also performing some character-building activities like sweeping out the shop and occasionally helping unload farm equipment from a flat car at the town team track. Glenn attended the University of Kansas in Lawrence, receiving his Bachelor’s and Master’s degrees in Aerospace Engineering. Following college, Glenn went to work at McDonnell Douglas in St. Louis, Missouri. There he met and married Jane, who for some unfathomable reason is still with him after more than 43 years. In 1979, Glenn & Jane moved to Denver, and Glenn went to work for Martin Marietta. Glenn spent many years performing shock, vibration, acoustic, and loads analyses for various rocket programs with Martin Marietta/Lockheed Martin/United Launch Alliance. He wrapped up his career as an integration manager responsible for ensuring NASA and Air Force spacecraft were mechanically, electrically, environmentally, and functionally compatible with Atlas and Delta launch vehicles. Glenn participated in rocket launches from both Cape Canaveral Air Force Station and Vandenberg Air Force Base. Probably the most exciting (and nerve-wracking) was NASA’s Mars Science Laboratory mission, which placed the Curiosity Rover on Mars. Following retirement, Glenn & Jane moved from Conifer down to Lakewood, and Glenn became a member of the Front Range Division of the NMRA, and the Lockheed Martin model railroad club. In addition to model railroading, Glenn enjoys taking classes on a wide range of topics through Osher Lifelong Learning Institute (OLLI) at DU, and he hopes he and Jane will be able to continue traveling.

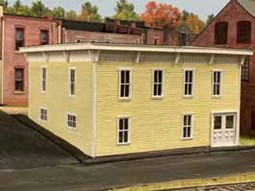

Another title for the clinic could be “Constructing a Women’s Boarding House Suspiciously Close to the Railroad Tracks in Salida, Colorado.” Glenn is using material from “Monster Modelworks” which includes wood embossed sheets with a brick or stone pattern. The Monster’s come from Larkspur, Colorado.

The building that Glenn has constructed is a brick building. During a long period of time, from 1939 to 1960, the building was stucco faced. The Scenic Line Modelers layout is set in the 1920’s or the 1940’s, so the modeler can choose the brick façade. The building itself is unremarkable other than the fact the Scenic Line Modelers layout has limited space for town development in Salida and this structure could be placed in a near prototypical location. The small structure across the street from the modeled interest is another Glenn model of the structure noted in public records as a “female boarding house”. Further investigation revealed that almost every building on the block was noted as a “female boarding house”. For the model railroad, the “red light” district of Salida is well represented.

Laura Evans was a madam in the district and during the Spanish flu, she provided beds for the ill after suspending operations for that period. Further, she provided food and coal during the Depression years to those in need. She provided social services in Salida prior to the term being popularized. The county district attorney drove the operations underground in the 1950’s.

Monster Modelworks is a division of Larkspur LaserArt. The products are available in N, HO, S & O scale in a variety of patterns in brick, block, and stone.

The material is 1/8 inch thick and 1/32” thick. This allows the basic structure to be constructed in 1/8” material with the details added in 1/32” material. The beauty of the system is the availability of the arched frames, corners, columns, sills, lintels, coping, and cornices. This adds a level of detail to the structure.

The reasons for using this product for this building project was that no plastic kits were identified to kitbash for the structure; the prominent arch over the main door was available; the old brick sheet product from Monster was available to represent a brick wall in poor shape that basically needed the applied stucco finish at a later time; and Glenn had used the concrete block sheet on a previous modeling project.

The windows for the project were not commercially available, so Tichy Train Group windows were modified to make up windows matching the Google Street View images of the building. Working with the images and the window sizing

chosen, the overall building was estimated at 40 feet wide and 28.5 feet high. This scaling provided a good-looking structure. The sides of the building were more difficult to model as the current photos show the side windows bricked over. Again, estimating from the available photo, the side windows were narrower than the front facing windows. The side dimension was shortened to fit the model space and the wall steps were scaled in to fit the building look and feel. Both sides of the building were made the same. The rear of the building today has no doors or windows, but during the model era it was assumed that there was a rear door and some small windows for bathroom areas.

Building the structure required transferring the dimensions and openings to the back side of the sheet. The cuts were made, and openings squared up with sanding sticks. A circle cutter compass was used to cut out the arch to match the arch lintel. The windowsills, lintels, cornice and other trim parts were added to the outer walls. On the back of the building, the one opening ended up too large for the window treatment, the opening was filled using the clean brick sheet. This gave a different texture to the wall and the effect was used on two more windows.

The brick was initially painted with Rustoleum 2X Flat Red Primer. Roberts Brick Mortar Formula was thinned and used to highlight the mortar joints. This treatment is wiped off after a short drying period, but some trim parts buckled. The foundation areas were painted with Rustoleum 2X Fossil, which is a good representation of old brick. The roof was constructed of 1/16” basswood. This was covered in first aid tape and painted with Krylon dark brown camouflage. The Monster system includes column material which was used to fashion the chimney. The soil pipe was modeled with brass tubing. Window frames were painted with Rustoleum 2X Nutmeg with windows installed with canopy glue. The curtains were modeled from Window Designer software. The front wall windows have a stained glass panel above the clear pane window. The stained glass was modeled in PowerPoint and printed on transparency film. This adds to the distinctive look of the building.

These sheet products and details are available at: https://larkspurlaserart.com/monster-modelworks/

Check them out for your modeling needs.

February Clinic 3 – February 19, 2024

Trees, trees, and more trees

Rich Gibson Biography

This was the floor show portion of the clinics as Rich moved to the center of the room for a demonstration. Rich models the New England area. This requires a lot of trees on his layout, and he points out that he cannot spend much time on individual trees. He uses natural materials as he can get a good variety of shapes and forms from the materials that cannot be duplicated with commercial products. As this is primarily deciduous trees, the focus is on natural armatures with the shapes common to the desired model tree.

| Plant | Flock Size | Adhesive |

| Super Trees | Coarse Turf | Matte Medium |

| Oakleaf hydrangea | Coarse Turf | Spray Adhesive |

| Nandina | Underbrush | Spray Adhesive |

Other plants can be used as well; Crepe Myrtle, Sagebrush, Saltbush, Sedum, Goldenrod, Rabbitbrush. The key is to find material that the modeler finds suitable and experiment to make up your forest/tree. It is helpful to source the materials in the locale, so the supply is readily available.

The Supertrees material is purchased as a component or a kit. The component method allows more flexibility by the modeler to adjust the texture and colors for the trees.

Oakleaf hydrangea is an ornamental flowering plant that will grow in this area. The piece that the modeler desires is the flower head. After drying, the flowers may be stripped off and the resulting armature may be trimmed to the tree shape desired.

Nandina is an ornamental plant very common in the Tulsa area. Rich takes a box and fills it on his trips to the Tulsa area to insure his supply. The plant has two strikes against its growth on the Front Range of Colorado. Some varieties of the plant are considered invasive particularly the fruiting plants. Further, the plants are not winter hardy for much of northeastern Colorado. The fruit stems are the modeling material. For the tree armature, the berries and other vegetative matter are stripped off. The resulting armature can be trimmed to shape.

The key to making realistic trees is to match the size of the flocking material to the armature and to select the adhesive to match both the flocking and the tree armature.

Rich demonstrated his technique for making the tree from the Hydrangea. He selected a stem, removed the remaining flower petals, sprayed on 3M 77 adhesive, and sprinkled on the Woodland Scenics coarse turf. The tree was completed in 1 minute and 20 seconds during the demo with the explanation of what he was doing and getting the materials out of the storage container. Some stems have little pods attached and those are best combed out or picked off as they will show through the flocking.

He stepped into the tree process with Nandina. These stems are much tougher than the Hydrangea. Using a technique similar to the Hydrangea, pick off the remaining berries and remnants. Trim and paint the stem to form the armature. Spray the armature with the 3M Super 77 adhesive and sprinkle on Woodland Scenics underbrush as the flocking. A key to using these trees is that the base or bottom may not look the best, but in mass plantings, the lower part of the tree is obscured.

Supertrees need a little more preparation. When the modeler receives the box of Supertrees, it contains the remains of a “Norwegian Sagebrush”. These pieces have a good tree like structure but are oftentimes bent or curled. They need to be separated into model tree size stems. The stems contain small leaves. The leaves need to be removed. Don’t discard the leaf bits as they are useful in other modeling. The leaves can be used to model harvested corn fields and other small branch bits can be used to make underbrush and small trees. The armatures are best soaked in dilute mat medium and then suspend them vertically weighted to enforce a straight trunk. After drying, the armatures may be painted a grey color or other colors to model natural tree bark. To apply the flocking to these armatures, the branch structure is rolled in diluted mat medium keeping as much of the trunk out of the medium as possible. Sprinkle the coarse turf flock on the branches to the desired thickness. The resulting trees have fine branch detail and are suitable for foreground trees. The trees should be suspended upside down to fully dry.

To add fall colors to the trees, use a completed flocked tree and overspray the tree with cheap hairspray from the top down. Sprinkle the tree with fall color leaf flock in a straight color or mixing colors for variety. Overspray the tree again with hairspray to fix the colored flock. This technique can be used to add summer “leafy” appearance by adding slightly differing colors to the crown of the trees.

The modeler will need a selection of trees to add to the layout. Rich makes a lot of trees and stages them in foam or boards drilled to accept the trunks. A variety of material makes for a variety of tree types to add to the layout in an area. These are the trees ready to plant.

This is a box of small bits and pieces flocked and ready to add to the layout as the under story of the forested area.

Rich continued the clinic with a discussion of bottle brush trees as conifers for layout use. Spruce and fir trees have a classic conical shape. But pine trees have differing rounded shape profile. The materials that you need for this process is sisal rope and floral wire. The sisal rope is disaggregated into single strands of sisal fiber. These are the branch structure for the tree. For an HO tree, two inch lengths of sisal are used. This length can be adjusted for differing scales and differing masses of trees. Spread the fibers between the two lengths of floral wire anchored to a vice or in a tree jig. Twist the wire using a drill or the tree jig to anchor the sisal within the twisted wire. Cut the wire into tree length pieces with variations for differing height trees. One good point with this method is the branches can easily be trimmed back or eliminated all together to replicate the damage seen in nature. The trees can be shaped to mimic the shape of the type of conifer tree more closely. After trimming to length, the trees should be painted with camo brown, dark grey or black paint. The spray adhesive can be applied to the branch structure and the branches flocked with fine or coarse turf.

Since the video did not work on capturing Rich’s presentation from the floor, a separate time is being worked on to video Rich showing the work portion of the Tree presentation.

January Clinic – January 15, 2024

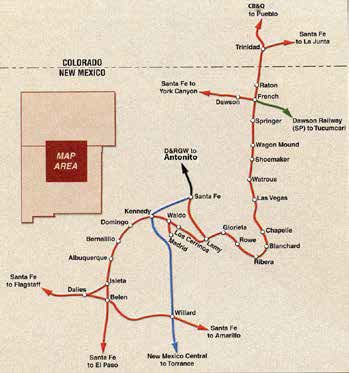

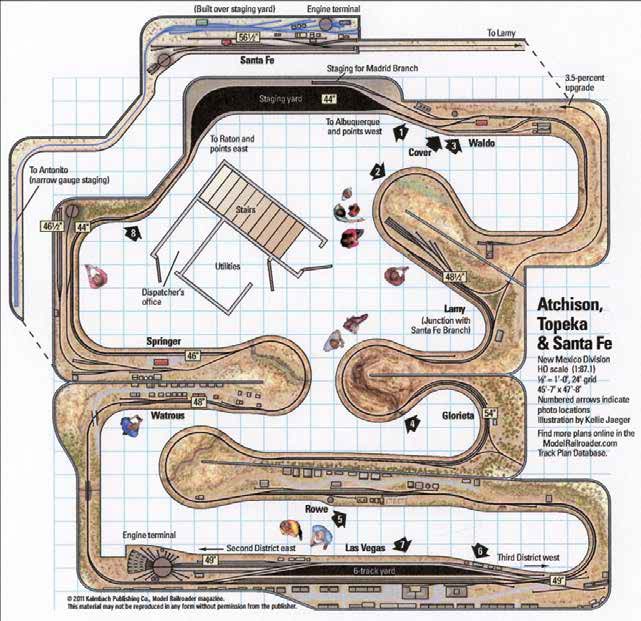

Modeling the ATSF Built Cars of the 50’s and 60’s

This clinic looks at many of the thousands of ATSF built and rebuilt cars of the 50’s and 60’s and some of their unique characteristics not found in commercially produced cars. We will look at some kit bashing techniques, added details, use of rivet decals, painting and lettering to represent these cars. Most of the kit bashing is commercial plastic kits and parts. The cars that will be discussed are boxcars of varying lengths as well as reefers.

Denny Krausman Biography

Denny was born and raised on a farm in central Iowa and received a BA Degree in Physics from Northern Iowa and later received an MBA Degree from the University of Colorado. He spent nearly 50 years in the Heavy/Highway construction business and retired several years ago.

Denny has been a member of the Santa Fe Railway Historical & Modeling Society (SFRH&MS) for nearly 30 years, and he models the Santa Fe RR in southeastern Colorado in HO scale with the time period of the late 60’s and early 70’s. He is a recent recipient of a Master Model Railroader Certificate #622.

During the past 40 years of modeling, Denny has built scratch-built models and a number of resin craftsman kits, as well as a number of kit-bashed cars. One of the things he enjoys most is researching prototypes, so he can accurately model what he is building. This has helped Denny to build a number of award-winning models. He has given a number of clinics on these topics and has been published in the SFRH&MS Warbonnet, NMRA Magazine, and Railroad Model Craftsman.

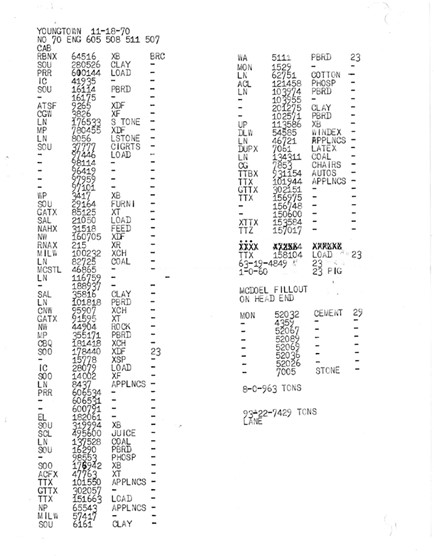

The January meeting for the Front Range Division was held via Zoom. The weather wasn’t kind to the group. Denny Krausman shared his presentation on Modeling the ATSF Built Cars of the 50’s and 60’s. As been noted several times, the second world war was hard on railroad equipment. The railroads needed new power and importantly new boxcars to handle the post-war boom in freight. With that in mind, the ATSF began a program to construct and re- build their car fleet. As an ATSF modeler of that era, Denny researched the Santa Fe cars and noted that the ready-to-run or even the kits offered did not match the photographs and builder plates, or car plans. To get the cars that he wanted, he set about assembling his model fleet from kit parts, individual parts, and by casting some of his own parts to make up the cars he wished to model. The Santa Fe community has several color and black and white photography books covering the cars of the era. The Santa Fe Modeling and Historical Society has a treasure trove of information on the railroad and its history.

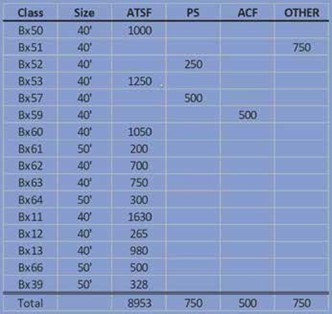

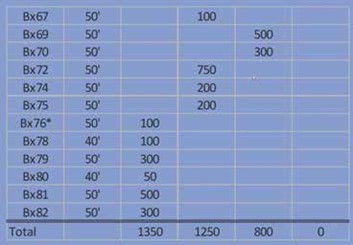

The ATSF had over the war years beefed up their car shops to keep up with fleet maintenance. After the war, car manufacturers could not satisfy the demand for new cars. The Santa Fe determined that with the shop capacity they could build their own boxcars as the parts were available. As illustrated in the chart, the Santa Fe Railroad built most new cars or re-built cars in-house. The chart also shows the transition from 40-foot cars to 50-foot cars as the years progressed.

Their preference was to utilize riveted construction. They purchased 750 Pullman Standard boxcars, PS-1, under the program but they were not satisfied with the welded construction, so they continued using standard riveted construction. As the clinic progressed there was a question on the use of riveted construction. At this point, it is still an unanswered question. The Santa Fe Railroad persisted in the use of riveted car construction into the 1980’s.

Santa Fe’s new standard boxcar, the Bx53, was a forty-foot boxcar with 4/4 improved dreadnaught ends, diagonal panel roof, lightweight Youngstown doors; and 12 panel sides. These elements were common to the series of box cars with the difference being the width of the doors and added panels to lengthen the car. Few commercially available models are available in this configuration. As was noted by John C. Bobyne III in his book, the use of improved dreadnaught ends in combination with diagonal panel roofs was common in Canada but not in the United States. It could be argued that the Santa Fe Railroad made this combination common in the U.S. as certainly 9000 cars noted on the chart is a large number.

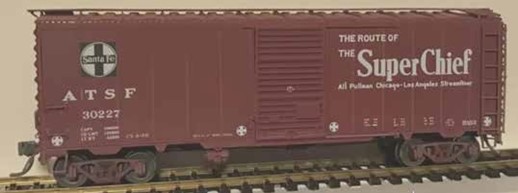

Denny was not deterred by the lack of commercially available models. He made a mold of the 4/4 improved dreadnaught ends from Branch line Trains and was able to cast as many as the mold would allow. The start of the car build was an Intermountain 12 panel box car kit. The roof was changed out to a diagonal roof at the time available from Branch line Trains, cast ends roughed out the Santa Fe version of the box car. Rounding out the car were doors and roof walks available from Kadee. After painting and decaling for the period, the result is a very nice prototypical car.

This process was continued for each individual car basically kit-bashing the car from an assemblage of parts. The beauty of the system is that the modeler can craft the model fleet to the period of the model era, and the number of the types of cars can be proportioned to the Santa Fe constructed fleet.

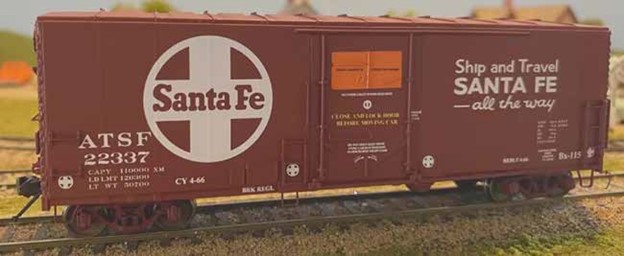

As time progressed, the construction efforts turned to 50-foot box cars, as the Bx66, above. These cars were 16 panels long with riveted construction. The cars shared the details of the 40-foot cars with 4/4 dreadnaught ends, and diagonal panel roofs. The doors were increased to an 8-foot-wide door. Added on each side of the door opening were diagonal braces from the outside edge of the adjacent panels to the door opening above. Riveted gussets at the lower edge of the door opening were added. These changes added some detailed elements to the car. The diagonal rivet lines can be added with rivet decals. The gusset plates are added pieces of styrene again with added rivet decals to complete the look. Moving to re-built cars we find the Bx39. This car was a war-emergency box car with wood sheathed sides. The car was intended to be re-built with steel sides at the war’s end. Santa Fe re-built the car with 16 panel sides, an 8-foot door, and the reinforcing details of the Bx66. One difficulty encountered with modeling this car is that since it was constructed early in the war period, it utilized 5/5 standard dreadnaught ends, which have a definite differing appearance from the 4/4 ends. An additional detail was a plate added at the car end to attach the stirrup step. For this series of cars, Branch line Trains produced a kit that had the characteristics of the Santa Fe car. This kit includes the spotting details of the 16-panels, 8-foot door, and an added plate for the end stirrup steps. The car included 4/4 improved dreadnaught ends which needed to be switched out for the 5/5 standard dreadnaught ends.

Adding the rivet lines on car was accomplished with Micro Mark rivet decals. The Micro Mark version of the rivet decals is a little larger and more pronounced, so after application and painting the detail matches the cast details of the cars.

This produced a great-looking Bx39 model to add to the fleet.

Using the same Branch line kit, the modeler may produce a Bx61. This example of the car is unique as it has white doors and the XF decal in the corner indicating that this is for food-loading only.

The profile at the ends of the car is somewhat different as the stirrup bracket plate is omitted. This detail was trimmed off the car body and the stirrup step sets back from the face of the car a slight amount.

In the late 1950’s, Santa Fe continued to purchase 50-foot cars from other manufacturers. The reason for the break in shop produced cars was that Santa Fe was retooling for the construction of their version of the shock control underframe cars. This adds new details and yields a different look to the cars.

The 50-foot cars from the Bx76 forward were all cushioned underframes. This car had a different side sill appearance. For this series of car models, the car sides were cut from styrene sheet. The total rivet detail configuration was applied with decals. The upper edge of the car was decorated with an additional styrene strip to match the prototype. The doors were glued in place. The sides were primed prior to rivet decaling as the decals need the tooth of the primer coat to adhere to the styrene. Basically, the car is just a box fitted to the frame. Tangent Models made a shock control underframe, and this was used on this project. The painting on this car is two-tone with the sill and upper car edge black with the remaining side red. The ends and the roof are painted black. Another element on the car is the SL logo in a circle at the end of the car. This decal was only available from Tichy.

This is a very distinctive model that really adds to the Santa Fe feel of the car fleet.

The car construction continued on with building and re-building of 40-foot cars. The Bx83 was a re-built 40-foot box car with a super shock control underframe. These cars were all dedicated to appliance delivery service to reduce freight damage during shipment and handling. The cars were equipped with 8-foot doors to facilitate loading. The result was a unique car.

In another customer-driven car type was the Bx85. This car is a rebuilt Bx12 that was given a new life in grain delivery service. The car sides were built with riveted construction and a plug door with grain inspection doors built into the plug door. While the industry was transitioning to covered hoppers for grain service, many of the Santa Fe elevator customers were not equipped to handle overhead delivery of the grain. These box cars were used to ship grain from the large number of small operations. To model these cars, one needed to find frames and floors built on the narrower dimensions of the Bx12. To extend the interior width of the car, an angle was used to place the sides at the wider width. To start the project, a Central Valley stock car frame was used. This has a narrow width to form the base of the car.

The car sides were built with styrene sheet to the dimensions needed and framed out in a box configuration. The correct end castings were available as Westerfield Models. The plug door was scribed into the sides. The panel rivet lines were marked on the sides. Tangent models provided the door hardware and that was attached prior to painting. The painting was a two-step process with the reefer orange sprayed first. The loading doors were masked off and the box car red finish coat was applied. This finished the car with the correct profile.

Santa Fe also re-built some of their Bx37 car fleet into similar grain cars, Bx115. Since the Bx37 was built in later years, the width of the car was appropriate. The cars sported reinforcing gussets on the sill of the car, basically three near each bolster point. The starting point for this car is a Branch line kit, 40-foot, 10 panel box car. The doors were scratch built like the Bx85, and the car painted with a two-tone paint scheme to highlight the grain doors. The bottom of these cars had a straight sill line and so the detail on the kit was removed and a styrene sill was added.

In the late 1960’s, Santa Fe built a new style of box car, the Bx94. This car had exterior bracing and wide plug doors. It was another in their series of shock control cars.

Moloco Trains made a copy of both the Bx94 and Bx97. They were good enough to pass for the cars and it was a matter of purchasing them.

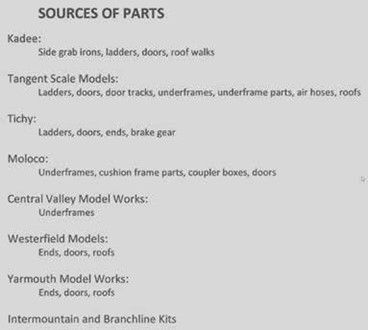

As we went through the presentation, several parts sources were noted. Some of these sources are still good but several of the suppliers have merged into larger companies and the products are no longer available from them. It is important to source parts as available at train shows, swap meets, hobby shops, eBay, and other on-line sources. One needs to be careful shopping on-line because of unscrupulous operators.

While this clinic has focused on box cars, Santa Fe rebuilt several other car types. The reefers were updated by the shops. The RR19 for example was re-built to a more user-friendly car. The icing hatch doors were modified to flip open to the center of the car. Drains were added to the ice bunkers to prolong the life of the car floor. Reinforcing plates were added to the sill. Doors were updated or remained the same. So, there is another clinic on the history of the Santa Fe reefers. Also, Santa Fe rebuilt gondolas, and flat cars. So, expect more to come! The questions were asked on the reason for the grain door box cars. This was customer accommodation. Smaller elevators could not afford to update their loading systems to top load covered hoppers. So, for those customers the railroad made available the plug door versions.

Denny was also asked how many cars he has on his railroad. He has around 300 cars of all types. More are needed to round out a representative fleet.

Clinics for 2023

December Clinic – Gathering of the Elves

December is the time for the Holiday Gathering of the Elves. This is a pot luck event, so it is time for the party recipes to come out of hiding and make an appearance. Start planning your contribution to the festivities. As is usually the case, chocolate desserts are preferred. Be sure to attend the November meeting to get in to the menu planning.

The Front Range Division holiday party will be held Saturday, December 9th, at 6:30 pm at Rich Gibson’s home (address and map below). Spouses, partners, or +1s are welcome. Janet and Rich will provide an appetizer, a dessert, soft drinks, mulled wine, and some beer. Please bring an appetizer or dessert to share.

Rich’s layout will be open for your review and adoration.

For planning purposes, please let Rich know if you will attend with the number of guests by December 4th to richgibson89@yahoo.com. Please join the Front Range Division for an enjoyable evening of model railroading fellowship.

As is the usual custom of the Front Range Division, the December meeting was a Gathering of Elves or a holiday party. Rich Gibson and Janet Schweitzer hosted the gathering at their festively decorated home. They also provided food to enjoy with a ham, Hawaiian sweet rolls, and drinks to enjoy. The potluck area was filled with other goodies including appetizers, salads, and of course desserts. The most sought-after dessert was the Chocolate Dream Pie which for some reason simply disappeared.

The event was well attended. The Maine Central – Portland Division model railroad was open for visitation. There were two new areas developed since the Division’s last visit a year ago. The Lewiston Branch was enlarged to add more switching action. The staging yard was moved across the train room to the eastern wall. This will give more operating space and more industry development.

A presentation was made to Keith Hayes. Keith earned his Certificate of Achievement for Model Railroad Author. This is one of the achievement certificates on the journey to Master Model Railroader. Congratulations to Keith for the milestone and keep up your good work.

November Clinic – November 27, 2023

1st Mini-Clinic of the Night

Glenn Runkewich Biography

Glenn grew up in the railroad town of Cheyenne, Wyoming. As a boy, he would ride bikes with his friends down to the Union Pacific tracks to watch the mile long trains coming and going from the famed Sherman Hill. After

high school, he attended the University of Wyoming on a debate scholarship in Laramie just the other side of Sherman Hill. There, he earned a BS degree in Economics and an MS in Business Administration. He moved to Denver in 1980 and began a career managing software development projects for several large telecommunications firms finally retiring from Comcast as a senior systems architect. During this previous life, he was also an avid white water boater rowing his raft down many of the west’s major rivers including three trips through the Grand Canyon.

Currently in addition to model railroading, Glenn enjoys traveling, skiing, and music. He plays regularly with the Pueblo Drum Tribe, and creates music videos he posts on his YouTube channel. They can be found at YouTube.com/@HowlingCatSoundAndImage. He and his wife Diane split time between Highlands Ranch and their cabin in Northern Wyoming. They have a son, two grandsons, and two very pampered goldendoodles.

Glenn’s mini-clinic will concern the Sylvan Models HO Scale Laker Class Freighter Kit. He will clinically explore the challenges presented in constructing this kit, modification and additions he made, the history of these ships, and online resources available for research on the prototypes.

Glenn Runkewich shared his experiences constructing a freighter model for his layout. The SS Jack Brody started its life as a Sylvan Models HO Scale Laker Class Freighter Kit.

Glenn has been building ship models since he was a youngster and has completed two models as an adult. The ship models are very delicate and should be displayed under a cover. Seeing as how Glenn has a model railroad, he has a good display area for his ship project. The available ship models in HO scale and N scale are very few and are mostly larger models than could be accommodated on the HO layout.

This is a resin kit that follows a prototype ship. The instructions refer to the box top at several points, and many of the details are obscured. This ship is a model of the WW I Laker Class ship which is the equivalent to the WW II Liberty Ships. The United States Shipping Board which during the First World War assumed the responsibility for maritime activities, similar to the United States Railroad Administration. The Board used standard designs for construction of the various classes of ships. Using these standards, ship construction numbered 431 in 1917, 535 in 1918, and finally 1180 in 1919. Of note here, is that production ramped up and exceeded the number of ships needed after the end of the Great War. As this was a government operation, we needed an accounting of the costs of the ships. This ship building exercise employed 350,000, built 8000 houses, 9 hotels, 900 apartments, 21 dormitories, 11 cafeterias, 2 schools, 81 stores, and one hospital. So, the results of the effort was the establishment of a ship-building infrastructure to put the U.S. on par with the remainder of the world.

The model is fashioned after Design 1020, which was intended to be used in the Great Lakes. The Welland Canal Locks were 270 feet long, 45 feet wide, and 18 feet deep. The 1020 was 261 feet long, 43 feet wide, and 22 feet maximum depth. This means the ship could not transit the locks fully loaded but could use the locks empty or with a partial load. It is okay as the war effort would require the fully loaded ships to transit the Great Lakes after the locks and continue to Great Britain. This hull design was used in a number of configurations and between 400 to 500 ships were constructed by the Great Lakes ship builders, by West Coast ship builders, and Canadian builders. The specific design 1020 has several specific features to use as spotting hints. The ship has two masts with ratlines, a walkway in front of the bridge, and a small pilot house. On the interior, two coal fired boilers develop 180 psi in a 1500 HP triple expansion steam engine. This will propel the ship at 9 knots (10 mph) until the fuel is exhausted. At least 35 of these specific configurations were constructed.

The difficulty is too many ships were constructed, and the U.S. ship building industry collapsed. The ships were sold to many nations and domestic operators. A number could be found on the West Coast working lumber operations. Ford Motor Company purchased 150 ships for scrap. The ships were utilized by all combatants in World War II. The final examples of these ships were scrapped in the 1970’s. From the modeling side, the long life of the ships means it had a 50-year life span of where the ship and the model would be appropriate on the layout.

Since the instructions were a little vague and imparted little history to the layout model, Glenn researched the ships in their use. Photographs were available on the internet of the lake class of ships and showed a number of variations to be considered for the model. The photos showed two or four lifeboats, four life preservers or none, an aft gun platform or not, and antennas were visible on some photos. Using modeler’s license, four lifeboats were modeled including four life preservers on the pilot house. Most importantly, the photos showed the rigging for the ships with pulleys and doubled lines visible in the black and white photos. Glenn went through the rigging for the ship in detail illustrating the complexity.

The modelers’ resources that were used in the kit construction were:

- Kit Instructions: History, Assembly Diagrams

- Internet Images: Prototype Photos, Model Photos, Artist Portrayals, 1020 Plans

- Mainline Modeler Magazine: Extensive History, 1099 Plans, Prototype Photos

- San Francisco Maritime National Park 1943 Deckhand Training Guide: Extensive Rigging Descriptions and Diagrams

The model itself is a blended prototype with features not following any specific prototype. Remembering these ships were constructed by numerous ship building enterprises, many variations were built on the ships and with the long length of service, many modifications and repairs were performed on the individual ships. Some of the items were included to assist in the construction of the model, and others were an application for an artistic license.

The kit is a resin kit, and as such, the detail is not as fine as styrene models, and it is thin meaning it will warp and twist. The kit was assembled and sometimes re-assembled with plenty of super glue. As these kits have a lot of flash and the fit is not exact, a utility knife was used to clean up and carve the kit to allow the build to proceed.

Details were added to the model to add interest in the ship. All rigging was added, porthole glass, scupper bars, stairway rails, light sconces, weather deck braces, ship name, American flag, life preservers, small cowl ventilators, spare anchor, loose cargo, pallets, figures, bridge and pilot deck support posts, boom cradles, modified steam piping, funnel seams, eyebolt plates, chart table, and night lighting rounds out the list of added or enhanced items on the ship. Additional details were sourced from Cast Your Anchor; ships bell, cleats, medium size blocks, and cargo hooks. This is an extensive list, so the ship kit was a starting point for the building effort.

As noted the rigging was explained in detail and those interested should refer to the 1943 Deckhand Training Guide for a full explanation.

Since this model is to be installed on the layout with other lighted structures, lighting was added to the ship in the pilot house under the chart table to disperse the lighting. The light flows into the bridge and further adds indirect lighting to the walkways below. This gives a great nighttime effect.

2nd Mini-Clinic of the Night

Rich Gibson Biography

Rich grew up in suburbia on the east side of Cleveland, Ohio and became fascinated by rocks and minerals at an early age. In 7th grade, Rich thought it a good idea to correct his science teacher’s geology errors …. it wasn’t. Rich attended Allegheny College, majoring in Geology, and followed this up by earning an MS and PhD at Virginia Tech. Despite always wanting to pursue an academic career, there were very few positions available when he was graduated. Thus, Rich ended up joining Amoco and worked for them, and their successor BP, for 21 years on oil and gas exploration and production projects in numerous parts of the world. His early retirement in 2010 lasted 2 weeks before he joined Apache. 3½ years later joined SM Energy where he retired in 2023. He and his wife (Janet) tried to get located in Denver in the early 1990’s, but took a rather circuitous route, moving 8 times and finally ending up here in 2016. He has always had a general interest in history, and enjoyed traveling and hiking. However, Rich’s activities over the last ten years have become increasingly rail related.

Rich will continue with the overall theme of the mini-clinics with a short version of “Building Bath”. This will describe his attempt to reproduce the appearance and operations of a crowded Maine shipbuilding town in a limited space.

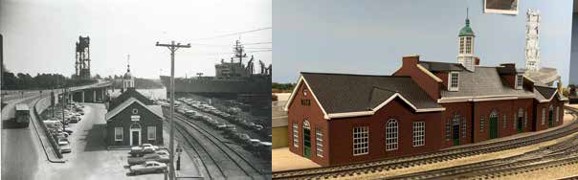

Rich Gibson continued with his clinic concerning his Maine Central-Rockland Branch which includes a representation of Bath Maine. Bath Iron Works is a major employer in the area and continues to be a military ship building center. During his modeling period, the railroad and the highway were carried over the Kennebec River on a one half mile long bridge. In 1919, the bridge had not been constructed and ferries were used to get trains, passengers, and everything else over the river. The bridge was completed in 1927 and carried the railway and the highway over the river. This changed the river front area of Bath and created opportunities for the railroad and shipyard to redistrict the area for continuing use.

There were some difficulties encountered in modeling a representation of Bath on the Rockland Branch. The first compromise is the Bath Iron Works is represented by a crane and a spur track. The iron works size is too large to fit in the model area. Secondly, the commercial district, of Bath, including the coal dock is rotated to be more perpendicular to the modeled river. This maintains the integrity of the trackwork and keeps the operational simplicity for operations in the area.

One of the signature buildings in Bath is the Maine Central Depot, which was paid for by the U.S. Navy to show a more substantial presence to the visitors to the Bath Iron Works. The model of the depot was constructed by Richard Segal of RightOnTrackModels based on the prototype photos and using the footprint available in the Bath track/bridge area. The depot model ends were skewed to fit the curve, as of course, the modeled curve is much sharper than the prototype track work.

To the right of the historic photo is the highway bridge being elevated to the lift bridge. This signature portion of the scene was modeled using gator board, PVC pipe, styrene, and insulating foam to build up into a realistic bridge. This structure forms a view block for the track to continue through the backdrop.

The next major item was kit-bashed for the Bath area is the shipyard crane. The crane was an amalgamation of the TYCO Gantry Crane and the Walthers Pier and Traveling Crane. The Walthers crane was too large for the scene and the TYCO was just not right for the scene. The TYCO gantry portion was utilized with the Walthers crane boom and engine house. The engine house was shortened to fit the gantry base, and the TYCO crane boom was re-purposed as the vertical jib. This yielded a substantial crane fixture in a small footprint. It is rail carried to move for loading and unloading.

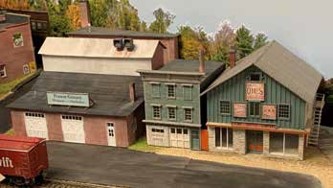

Continuing on the build out of downtown Bath, we come to MEC freight house. This was a long structure in Bath which was shortened for the model area. The building includes a large number of doors each one adjacent to another. The structure was constructed of bass wood with a nice uniform roof line.

The elevator on Commercial Street was the next undertaking of the Bath modeling. This building was a combination of a Campbell grain elevator, shortened to make it more typical of a New England style elevator, and a Fine Scale Miniatures portion of a kit. This gives the structure more width along the street and adds to the business feel of the area. It also adds a covered dock area at the street.

The next bit of the commercial district is the Pipe Company and the Torrey Roller Bushing Works. The Pipe Company was noted on one of the early Sanborn maps as the pipe company and was later noted as a water works building. The Pipe Company is a nice square building with a flat roof. It was constructed from bass wood structure braced to prevent warping.

The Torrey building complex was a combination of four eras of construction with differing architectural detailing. The portion with the most interest is the part with arched windows set in the brick walls. The next sections had rectangular windows with differing styles. The arched windows were the most desirable feature to model. Model Builder’s Supply Line, now under the N Scale Architect line, has a building wall system which includes arched windows. The kit includes a brass sheet of window details that the modeler cuts and folds to make up the arched windows and the mullions within the frame. The kit includes brick facing material that can be cut into the building wall shape. This formed the basis for the arched window portion of the structure with the square windowed areas built with Walthers windows from the scrap box. (No, we do not know what kit they came from.) The prototype building had four sections, but the modeled structure was modified to three sections to get the feel of the stepped appearance of the structure.

Another business to model in Bath was Prawer Wholesale Grocery. This was a rail served grocery warehouse that unloaded the products from boxcars and refrigerated cars and moved them across the street into the business. This gives an opportunity to drop more cars on the street. The building was put together from a couple of photos and sized to fit the area available on the layout.

Wrapping up the commercial business area of Bath, we have two unique businesses. The Acme Supply Company and Nadeau’s Garage. The Acme building was constructed from a single photo, squared up and sized to fit at the end of the street. It was a basswood building with scrap box windows and doors. The interior is yet vacant as there needed to be washers and stoves added to the display. The rockets and explosives are sold out of the back of the building. Nadeau’s Garage is a shady looking operation probably subsisting on small engine repair and service.

The final structure completed to date for Bath was the coal pocket. Again, this is a space constrained item and area. For this a box of sticks was purchased with a large coal pier. The item was intended to model outbound coal shipments. The rail cars were to be unloaded and coal transferred to ships or barges. In this instance, the coal is inbound, and the gondolas are at grade. Part of the kit was used to construct the Bath coal pocket. The height was reduced, the derrick and boom were shortened to make it believable, the head house and powerhouse were combined and constructed of gator board with wood siding sticks applied. The coal chute was centered over the structure and tracks.

This is the resulting overview of Bath.

Since we are model railroaders, there is always more to add to the scene. A crossing tower is missing to control the traffic on the tracks. A unique scale house must be constructed to fit the scene. This structure appears like an elevated covered bridge over the scale track to weigh primarily the coal hoppers. The customs house needs to be outfitted to match the existing customs house in Bath. The primary emphasis will be to modify the roof lines and ornamentation. The coloring will be changed to the white tone of the existing building. Lastly, a collier will need to be constructed to service the coal pocket. This is a difficult build as it must be about ½ of a ship model and much shorter in length than the available models.

October Clinic – October 16, 2023

Due to an unfortunate scheduling difficulty, the regularly scheduled meeting was unable to meet in the usual room and was canceled. The clinic, which was schedule “How Fred Harvey Opened Up the American Southwest” by Christine Petty, has been rescheduled for Monday, January 15, 2024. The next clinic in the schedule has also been moved from Monday, November 20, 2023 to Monday, November 27, 2023.

September Clinic – September 18, 2023

The Denver and Rio Grande Western – Monarch Branch

In this clinic, Gary Myers will review the evolution of the Monarch Branch and its importance to the Colorado Fuel and Iron Pueblo Steel Mill. This branch started as a narrow gauge rail line to the mine near the summit of Monarch Pass. The route utilized two sets of switchbacks and grades up to 4.5%. The line was operated seasonally most years from May to November. In 1956, the track was converted to standard gauge and extended to Salida. This removed the necessity of transloading the ores at a unique rotating barrel in Salida.

Gary Myers Biography

Gary Myers is currently living in Aurora with his wife, Michelle. They have two little 7 year-old Shih-Tzu brothers, Thor & Loki. His son Alex is 31, and lives in North Detroit. Gary is on his 5th Ford Mustang, a yellow 2005 GT.

Gary grew-up in Michigan, and graduated with a BA in Aerospace Engineering at the University of Michigan. From 1981 to 1985, he lived in the Bay Area – Sunnyvale, CA., and worked at Lockheed Missiles and Space on spacecraft and Titan 34B launches from the Blue Cube (later Onizucka AFS).

He moved to Denver in January 1986 and has been here ever since. He worked at Martin Marietta, Lockheed Martin, and United Launch Alliance until 2016. His worked involved trajectory analysis for Titan IV, Titan II, Atlas IIAS, Atlas III, and Atlas V rockets. During this time he earned a MS degree in Space Operations at the University of Colorado.

Since 2017, he has been working at the Aerospace Data Facility at Buckley Space Force Base. He is currenly working on cyber hardening of industrial control systems.

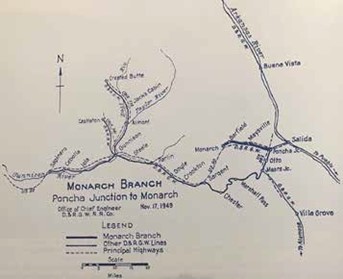

Gary Myers presented his clinic on the Inspirational Operational Marvel that was the Monarch Branch of the Denver and Rio Grande Western Railroad. This branch was extended from Poncha Junction (milepost 220.1) to Maysville (milepost 227.0) in 1881 and then extended to Monarch (milepost 236.3) in 1883. The line was a three foot gauge railway with maximum grades of 4.5%. The line had a double mule shoe curve located at Maysville (milepost 227.0) and a double switchback at Garfield (milepost 233.4). This difficult railway geometry made for challenging operations. The railroad was located in a valley for the approach to Maysville at a grade of 3.8%. One mile beyond Maysville the grades became 4.5% up to Monarch.

The railroad was constructed to access the gold and silver mines at Monarch. One of the principal mines was the Madonna Mine which had a tramway constructed up the slope from the loading tipple to near the crest of the mountain. Gold and silver mining was abandoned in the 1890’s. In 1924, limestone was quarried by the Eclipse Mining Company with a competing operation, the Burton Limestone Quarry opening in 1927. This material was an important additive to the CF&I blast furnaces in Pueblo. So, naturally the mine was purchased by CF&I in 1931. The branch remained viable until the blast furnaces were shut down in 1982. This railway existed for nearly one hundred years along its established geometry. It was operated year round even when rotary plows were required.

The importance of the operations can be noted in the six day schedule with the light schedule on Tuesday/Thursday/Saturday and basically a double schedule on Monday/Wednesday/Friday. It is important to note that this was a narrow gauge line for most of its life and the loads delivered to Salida needed to be transferred to standard gauge equipment for the remaining journey. The traffic on the line was broken into two or more parts to allow for the length of the switchback tails and the length of the available sidings. The two engine trains were more efficient on the line as the split trains could be handled by separate power without backtracking. The single engine trains were required to deliver the ten cars and return to Garfield to pick up the next ten cars for the tipple.

Salida/Maysville Operations

- First Crew Call: 4:00 am

- Report to Work: 5:30 am

- Train to Monarch

- M-W-F: 2 Engines / 56 Empties / Caboose

- T-Th-Sat: 1 Engine / 28 Empties / Caboose

- Maysville: Stage Half of the Train

- One half continued to Monarch

- Road / Helper return with 10 to 14 loads

- Return to Monarch with 2nd Half of Empties

- Return to Maysville with another 10 to 14 loads each

- Return to Salida around 3:00 to 4:00 pm

- M-W-F: 2 Engines / 40 to 48 Loads / Caboose

- T-Th-Sat: 1 Engine / 20 to 24 Loads / Caboose

- Second Crew Call: 1:30 pm

- Report to Work: 3:00 pm

- Train to Monarch

- 1 Engine / 28 Empties / Caboose

- Return to Salida around 1:00 to 2:00 am

- 1 Engine / 20 to 24 Loads / Caboose

It should be noted that the train lengths were longer on the inbound side than the outbound side, meaning that there were additional moves beyond the noted schedule moves to keep the sidings available for the inbound traffic. The characteristics of this branch were the restrictive lengths of the sidings and the switchback track which kept the train lengths short, and the movements carefully orchestrated. These operational difficulties add appeal to modeling the branch.

Garfield Operations Arrival

- Maximum of 14 Gons + Engine + Caboose fit on upper tail of Switchback

- M-W-F: 2 Engines / 28 Empties / Caboosse

- Train split in half

- Road Engine take first 14 cars up switchback

- Helper would take rear 14 cars up switchback

- 28 Car Trains had 1 Engine / 28 Empties / Caboose

- 14 Cars left at Maysville

- Road Engine take first 14 cars up switchback

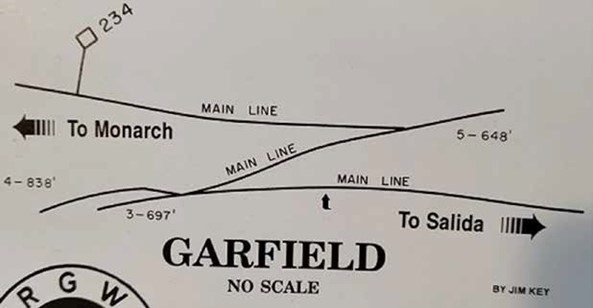

As the map notes the lengths of the switchback tails are 697 feet and 648 feet. The severely restricts the length of trains to operate through these areas. It is important to remember that while this is noted as a main line, the reality is that this branch is just that, a branch line with limited traffic.

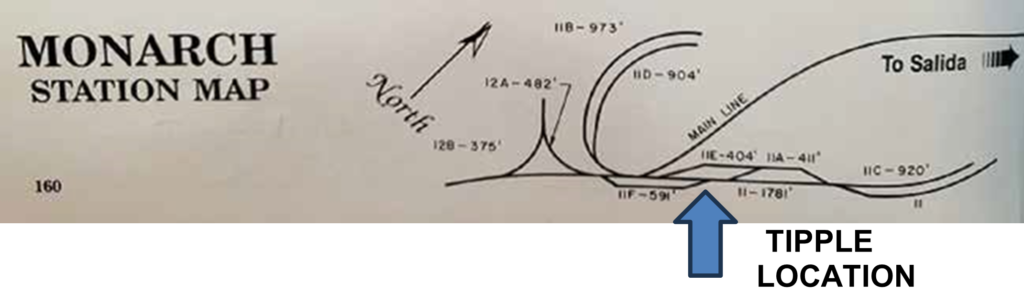

This map shows the trackwork complex at the termination of the branch. To the far right are two empties’ tracks where the empty hoppers are stored to be gravity fed to the tipple location. After loading, the cars continue to be gravity fed to two long curved tracks, noted 11B-973’ and 11D-904’, where the engines retrieved the loads. The power was able to pull the loads up the track to continue back on the main line to Salida. The wye allows the engines to be turned to manage the loads. The wye at Monarch yielded a tender step for Gary Myers as it was used to help locate the tracks after the line was abandoned and salvaged.

Monarch Operations

- M-W-F: 2 Engines / 28 Empties / Caboose

- Road Engine shoves empties up gravity tracks

- Turn Engines on Wye

- Road Engine pulls out 20 to 24 loads from load tracks

- Helper runs light ahead to Garfield Upper Switchback

- 1 Engine / 28 Car Train / Caboose

- Road Engine shoves empties up gravity tracks

- Turn Engine on Wye

- Road Engine pulls out 10 to 12 loads from load tracks

The Garfield map above can be used to help understand the departure operations at Garfield or more specifically the switchback moves needed to continue back to Salida.

Garfield Operations Departure

- Maximum of 14 Gons + Engine + Caboose fit on upper tail of Switchback

- M-W-F: 2 Engines / 28 Empties / Caboose

- Road Engine cuts 10 cars from train, proceeds down switchback

- Helper backs on upper tail of switchback and brings rear down to siding

- Helper cuts off train, runs light to Maysville

- Road Engine connects both halves of train runs to Maysville

- 1 Engine / 28 Empties / Caboose

- Road Engine cuts 10 cars from train, proceeds down switchback to siding

- Road Engine returns up switchback to retrieve rear of train